codes, easily insulated and has form finished wall faces to accommodate any cladding

Elimination of form ties, lightweight forms & simplified bracing

Vertical integration

Economies of scale

Advantages of No-Slump Concrete

*Formwork

Exerts little or no hydrostatic pressure when at rest.

Enables lighter and simpler forming system due to 98% reduction in hydrostatic pressure.

Simpler corner forming.

Less/simpler bracing

Eliminates form ties which saves money.

Faster stripping since concrete adequately sets up in about an hour.

No form ties provides unobstructed forms faces for form liners, or cladding placement.

Minimizes leaks since the vibrated concrete liquefaction is much thicker.

*Environmental advantages

Uses substantially less water per yard.

Less water results in substantial reduction in carbon created by hydration.

Uses fly ash which facilitates the disposal of a hazardous material.

Use of fly ash reduces the amount of Portland cement which produces high carbon.

*Quality

Less cracking due to less water.

Stronger due to lower water/cement ratio.

*Versatility

Elimination of form ties allows for easier and greater flexibility to insert liners, cladding, insulation, etc. inside the forms.

*Cost

Vertically integrated with all labor, equipment and materials.

Uses typical inexpensive pearock concrete mix.

Does not require costly additives.

*Building Codes

Meets all building codes and industry standards.

Thixcon is based on the thixotropic properties of no-slump concrete. This means that freshly mixed no-slump concrete only exerts hydrostatic pressure when vibrated. Therefore, by internally vibrating small amounts of concrete at any one time, only minimal hydrostatic pressure is exerted on the forms. See below video for system overview.

Interior side with foam insulation between and plastic studs and top & bottom plates

Exterior side with plastic studs embedded in reinforced concrete covered with elastomeric coating

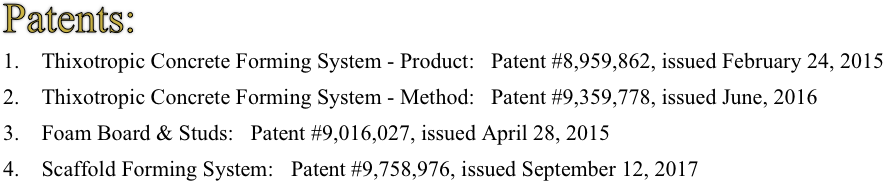

See patents below

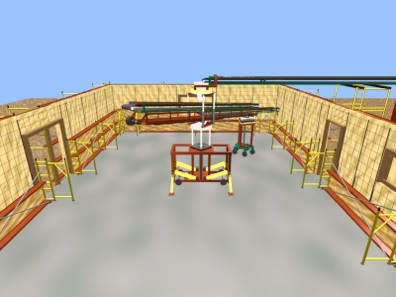

As shown in the video the process uses a low cost, job-site mixed concrete moved in specially designed conveyors from the mixer into the forms. The forms are filled in 16” lifts and internally vibrated. Costs projected at about $4/sf for 4” reinforced concrete wall using $30/hr labor and excluding profit & OH. The low costs are due to several savings from the elimination of hydrostatic pressure as well as specially designed forms, braces and equipment that dramatically lower labor costs. (See above video for details.)

The concrete is jobsite mixed and must be conveyed since it is too stiff to pump. While one side of the form is fully installed before casting, the second side is installed during the casting process to visually ensure the no-slump concrete is sufficiently vibrated.

See patents below

Optional foam board and plastic studs may be used as stay-in-place forms on the interior side to produce and insulated wall to which wall-board is attached.